Pipes prototyping is a delicate and complex process: for this reason the choice of the right partner in this field must be done with accuracy.

Scientific studies and professional experience have shown that in order to produce high quality prototypes in a short period of time the following points are MUSTs:

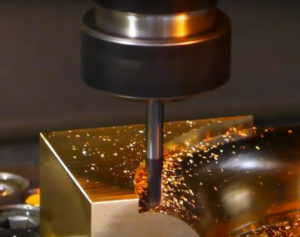

1) Internal manufacturing of special tooling for prototyping

Prototypes require the manufacturing of gauges and special tooling for the requested particular.

Having the possibility of manufacturing these tools internally is a recipe for quality and it reduces the manufacturing costs by 14% and the lead time by 17%.

2) Excellence in welding and brazing

Many prototyping projects require, at least in the first stages, a manual welding.

The ability and experience of these special workers is essential in order to produce high quality results.

3) Experience in prototyping

The experience in prototyping is essential and require a collaboration between experienced engineers and workers, in order to find the best solution both from the quality and the finantial points of view.

S.B.F. Tubi has has a 20 years of experience in the prototyping of metal pipes (iron, steel, aluminium, copper and other alloys) that require bending, deforming, welding and brazing processes. Moreover our company is specialized in the manufacturing of pressure-test masks.

Our team that works on prototyping includes a senior engineer, two quality experts and a group of experienced workers.